The hot rolled articles are first immersed in a weak solution of sulphuric acid to remove the scale and washed in water, and then dried. Seamless.exe see animation tapany udomphol 56.

2D FEM model representing the hotrolling process a) at

Easy to work in hot form.

Hot rolling process animation. While steel and alloy steel annealing is common, other metals can also benefit from the process, such as aluminium, brass, and copper. The product is free from stain hardening. The rolling mills are similar to that used in hot rolling.

The pierced billet or hollow shell is rollreduced in outside diameter and wall thickness. Our flexible service offerings can be. As the title suggests, it reduces the residual stresses that may have been caused by hot rolling, welding, or cutting.

Evaporative cooling is the process where warm water from an industrial process is pumped up to the top of the cooling tower where the water distribution system is. Plastic & chemical trading | plastrading | technical. The steel is cast into slabs, which are then rolled into hot rolled coils in the hot strip mill & thin slab caster.

From this step the tube goes through the straightener. The rolled tube simultaneously burnished inside and outside by a reeling machine. The action of the rolls causes the metal to flow over and about the mandrel to create a hollow pipe shell.

And, this process is carried out below the recrystallization temperature that is room temperature. This process of cleaning the hot rolled product is known as pickling. With this process, the steel is heated to a temperature below the critical temperature, resulting in little to no change to the material properties like there is with annealing and normalizing.

With tenor, maker of gif keyboard, add popular animated animated gifs to your conversations. Share the best gifs now >>> Molding processes for rubber •principal molding processes for rubber are:

This process completes the hot working of the tube. The hardness of material cannot be controlled after hot rolling and it is a function of chemical composition and the rate of cooling after rolling. Some of the hot rolled coils are further rolled into cold rolled and galvanisedcoils in the cold rolling mill.

Hot rolled steel is also shaped and formed by heating it above the recrystallization temperature. Hot rolling is a metalworking process that occurs above the recrystallization temperature of the material. The reeled tube is then sized by a sizing mill to the specified dimensions.

Search the world's information, including webpages, images, videos and more. The animation shows how it all works. Annealing also removes stresses that can occur when welds solidify.

Bar wire and tube drawing. Hot rolling processcold rolling processgrain flow in hot rolling processgrain flow in cold rolling processe4educationjoin our official telegram channel : Forging is a manufacturing process in which we obtain different shapes and sizes of a metal by the operation of hot and cold forging.

The hot metal is converted into steel through a steelmaking process called the ld process. In conventional hot stripproduction, slabs of thickness of about 250mm are heated in a furnace and arereduced to 30 to 60mm in thickness after passing through the roughing mill, andthen further reducing it to within a range of 0.8 to 25.4mm by rolling in thefinishing mill. The water then gets distributed by cooling tower nozzles to the wet deck.

The hardness obtained by hot rolling is less comparatively that of obtained by cold rolling. (1) compression molding, (2) transfer molding, and (3) injection molding compression molding is the most important technique because of its use in tire manufacture •curing (vulcanizing) is accomplished in the mold in all three processes, this representing a departure from Google has many special features to help you find exactly what you're looking for.

Continued… however most metal will experience some surface oxidation resulting in material loss and poor surface finish. These cleaned (pickled) products are then passed through rollers at room temperature. Other manufacturing processes like casting where liquid metals are poured into a mold and the operation are carried but when we talk about forging, the operation performs on metals.

Low force required compare to cold working. This is typically used on lower.

Simulation and experimental results of the hot rolling

Download Mathematical and Physical Simulation of the

Conventional type 3Hi rolling mill stands with volant

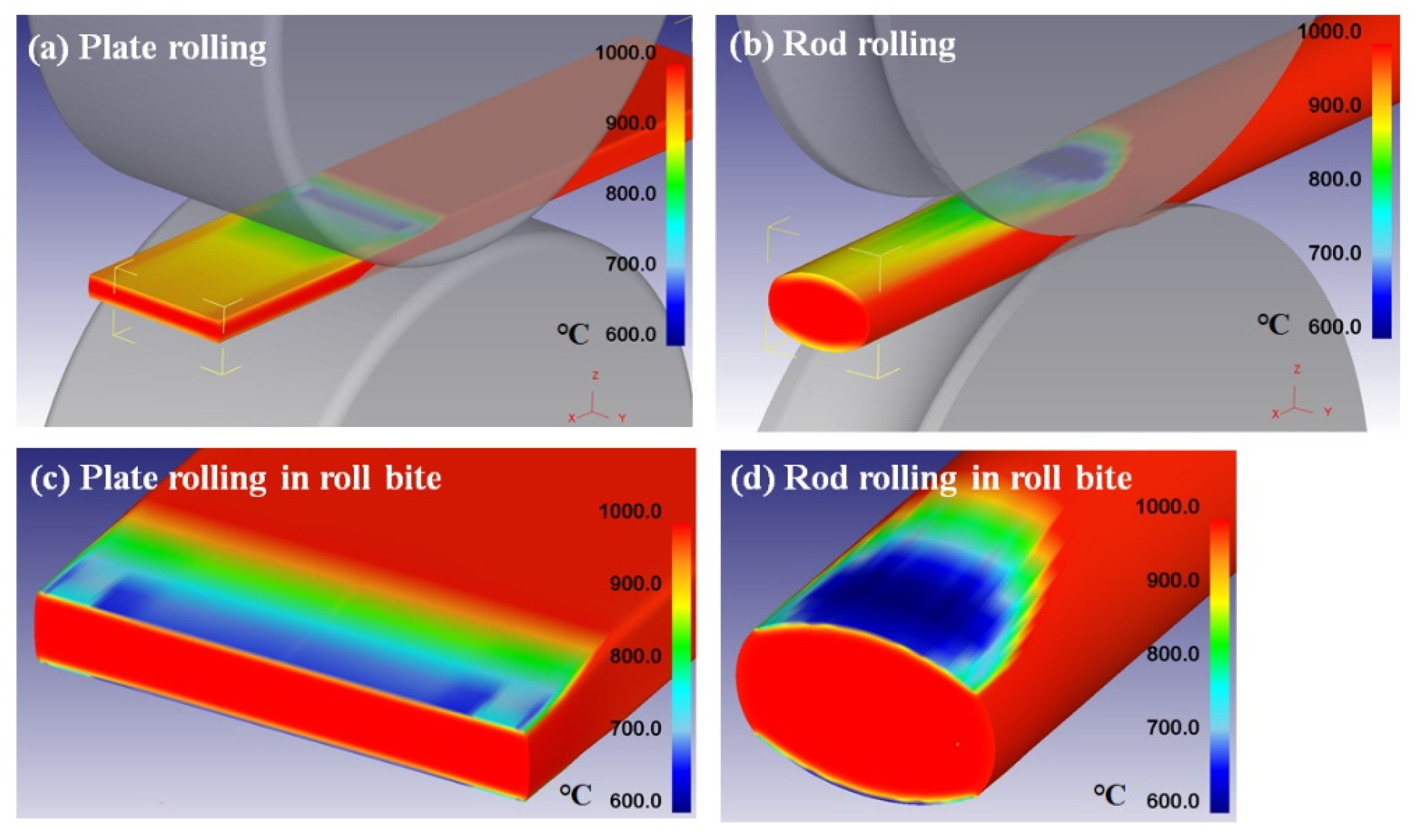

Processes Free FullText Thermal Behavior of a Rod

XRD spectra of hotrolled sample, IA750 sample, onestep

Rolling GIF Find & Share on GIPHY

EMG hotCAM Process reliability in the hot rolling

PROCESS ROLL CLEANER ANIMATION YouTube

Rolling Process Working, Application, Defects, Type of

GAZİ METAL RCM COLD ROLLING MILL

Hot Strip Mill (HSM) process animation Primetals

ROLLINGS PROCESS What is rolling process and how it is

Hot Rolling, Cold Rolling & Grain Flow in Rolling Process

Hot rolling processes in sheet metal. Download

XRD spectra of hotrolled sample, IA750 sample, onestep

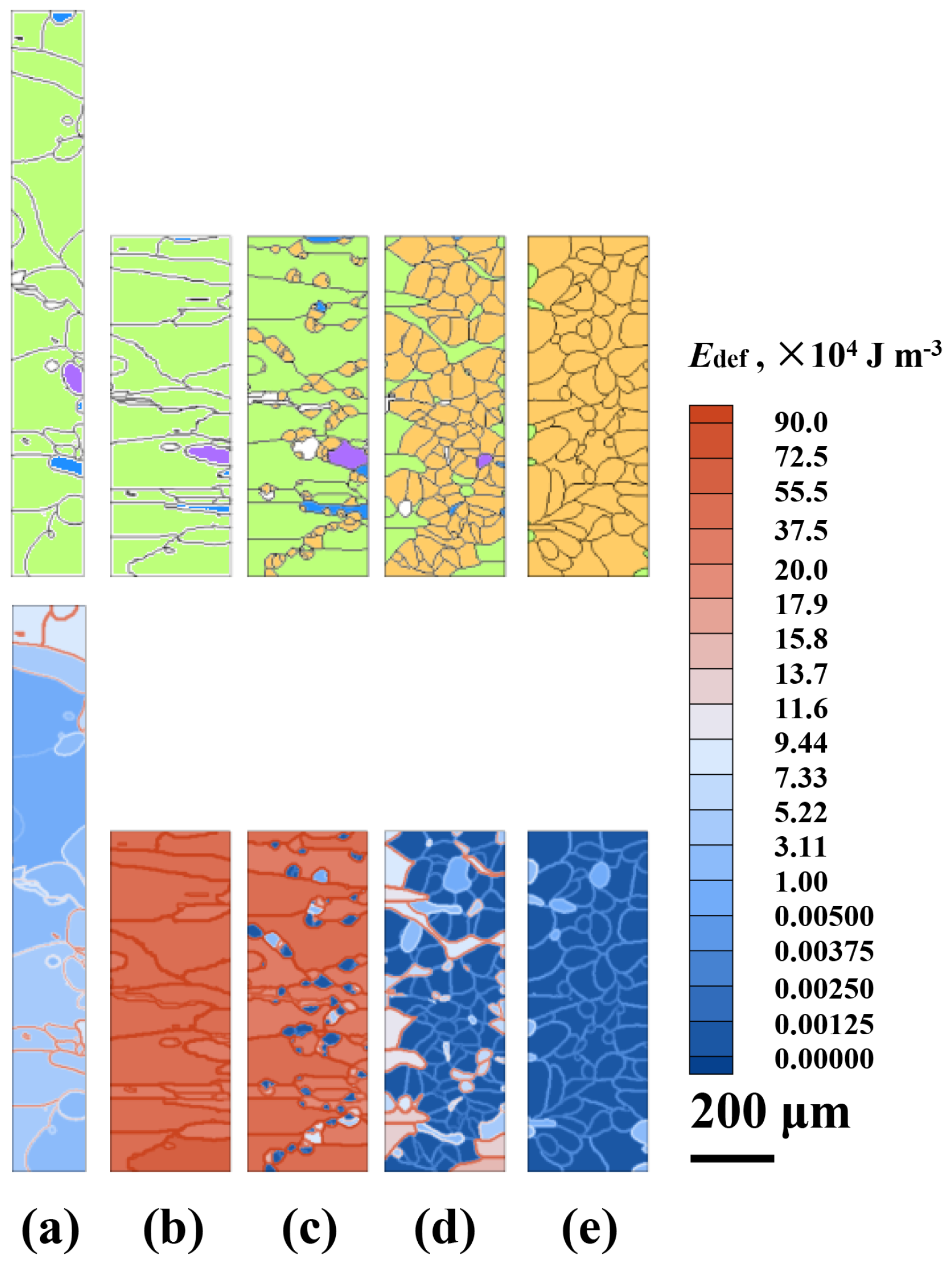

Materials Free FullText MultiScale Modeling of

XRD spectra of hotrolled sample, IA750 sample, onestep